Ever looked around your workplace and wondered why it's taking so long to get things done?

Wondering if there is a better and more efficient way to get things done?

The simple answer is a resounding yes! Using the 5S methodology, you can become more efficient in the workplace.

What is 5S?

5S is a Lean workplace method focused on organization, efficiency, and discipline.

It was developed in Japan by the Toyota Motor Corporation (yes, the same Toyota that makes the Corolla) as part of the Toyota Production System after World War II.

Toyota first used 5S to improve factory safety, quality, and productivity.

The name comes from five Japanese words describing good workplace practices. They all start with the letter "S" which is why the methodology is referred to as "5S". These are:

Seiri: Sort

Seiton: Set in Order

Seiso: Shine

Seiketsu: Standardize

Shitsuke: Sustain

This video explains the concept of 5S in a bit more detail:

5S Steps 1 & 2: Sort and Set in Order

Have you noticed how stuff like staplers or pens goes "missing" in your workplace?

This usually happens because the last person who used it didn't put it back where they took it from.

The 5S methodology proposes that you should be able to find anything in 30 seconds.

One way to achieve this is to use a Kaizen foam block to sort and organize physical objects. A Kaizen foam block acts as a visual reminder for anyone who takes something to put it back where it belongs.

This video shows how a person uses it to organize their desk.

This is just a starting point. You can also label empty space with the item that belongs there so that you know exactly what's missing.

But what about folders and stuff on your computer?

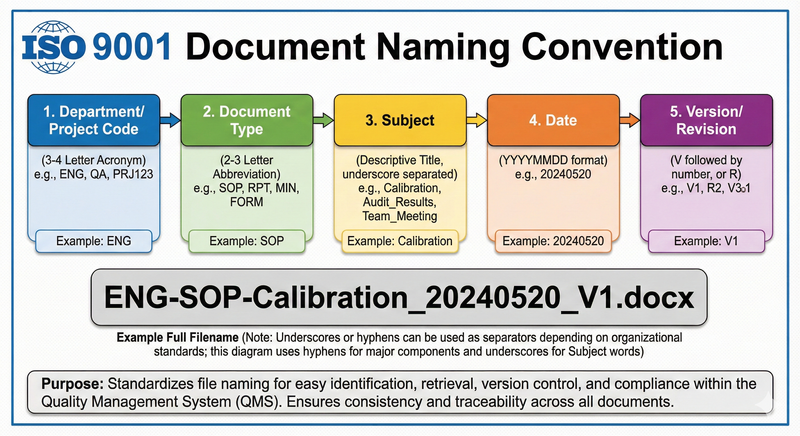

You can use a folder or document naming convention for organizing digital assets.

For example, the International Standards Organization proposes the following method to name your files:

Department/Project Code > Document Type (SOP, Report, Minutes) > Subject > Date, Version/Revision.

To hear an audio description of the image above, click the play button on the audio player below:

To hear an audio description of the image above, click the play button on the audio player below:

Did you know?

5S Step 3: Shine

Whilst step 3 seems like a given, the 5S methodology asks you to ensure you do it regularly and with purpose.

Ensure to address the causes of an unkepmt workplace as you organize the space you work in:

1. Making cleaning and organizing part of a routine. Label and back up your digital files as you work — don't push it off for later

2. Document the cleaning and organizing done. Use checklists and maintenance or cleaning logs to make sure the work done is recorded. This helps ensure continuity.

3. Identify and eliminate the root cause. Continuously make efforts to identify and eliminate the root causes of issues contributing to disorganization, waste, and unnecessary repetition of work.

A practical way to implement this is to have a time allocated for cleaning at the start of each day, or to have a cleaning timetable.

Identifying the Root Cause

Effectively identifying the root cause is very important to ensure we are addressing the correct problem.

The "5 Why's" methodology is a proven way to identify a root cause. Here a video that explains how it works:

Identify the Root Cause

In an assembly area, workers frequently stop to clean their workbench before starting each job. Tools are covered in dust and oil residue, and small parts are sometimes mixed with debris. This adds several minutes to every task and occasionally causes defects when dirt gets into finished products.

Thinking back to the 5 Why's, which “Why” question best helps identify the root cause of this problem?

A. Why are workers spending extra time wiping down their tools every shift?

B. Why isn’t there a standard daily cleaning and inspection routine for this workstation?

C. Why does this workbench get dirtier than other areas?

D. Why are workers frustrated with the cleanliness of the area?

Quiz

Select the correct answer below:

Subscribe for more quick bites of learning delivered to your inbox.

Unsubscribe anytime. No spam. 🙂

5S Step 4: Standardize

Once the previous steps have been put into action, you can begin the process of standardizing.

A popular method to standardize tasks is through standard operating procedures — also called SOPs.

Here is a short video explaining SOPs and why they're important:

There are many ways you can develop a Standard Operating Procedure.

This Microsoft articleprovides several practical methods to develop your own.

5S Step 5: Sustain

Last (but not least), you need to sustain the practices you put in place.

This is arguably the most important step, as it stops you and your team from going back to the old ways of doing things.

Here are a few simple steps to ensure you keep on track!

1. Set aside time. Schedule 10 minutes every day to make sure everything is in the right place.

2. Conduct a weekly 5S audit. Do random audits once a week to ensure that Standard Operating Procedures are being followed.

3. Promote ongoing 5S training. Ensure newcomers and those returning from long breaks are regularly reminded of the 5S practices.

Did you know?

5S Quiz

Your supervisor has asked you to manage the mailroom. It contains a photocopy machine, a large stapler for heavy documentation, and a large hole punch machine.

After taking over administrative duties for the mailroom, you notice that the large staple machine keeps getting taken out of the staple room. Once, it even disappears for several days.

What is the most appropriate first step you should take?

A. Secure the staple machine to the room using a locking cable.

B. Place the machine in a Kaizen foam template to ensure the user sees a message on the template reminding them not to remove the machine from the room.

C. Send an email to everyone asking them to follow 5S practices and also to return the stapler back to the mail room.

D All of the above.

Quiz

Select the best step to take:

Take Action

Here are some things you can do to immediately make your work more efficient:

Here are some things you can do to immediately make your work more efficient:

Your feedback matters to us.

This Byte helped me better understand the topic.